At this point in my career, working on the weekend is generally not what is done. But needs must when the devil drives and all that, a compound is needed for a study and it is needed soon. For that to work, sometimes you just have to put in a weekend shift to make it. Plus I figure that if I am having to work on a Saturday, at least I can get a blog post out of it.

There is an occasional Twitter topic called #realtimechem, so I will do something like that in considerably more than 140 characters.

So setting the scene: we have a compound that went into a study. They asked for some more and we took what intermediates we had to try and get the required amount. It looked like we would be short, but then they said they could finish the study with a lesser amount. Here I was guilty of too much optimism for I said that we might make that with what we have and it turned out I was wrong.

But wheels were set in motion and the deadline was set. We had more starting material in hand but in order to make it in time would need dedication, hard work and to not waste the weekend on trivial things like lazing about the house and telling off the kids for playing too loudly.

So Saturday morning dawns. First things first: check on the reaction I set up Friday evening. An alkylation of a phenol, often done with potassium carbonate as the base, here I found that to give me poor yields and cesium carbonate to be more effective. So I run the TLC to check the reaction is complete. I take a small sample out, add it to a mixture of ethyl acetate and water to take my TLC from the organic layer. The solvent is dimethylformamide which tends to mess up the TLC analysis, so I often do a mini work-up of the reaction to clarify matters.

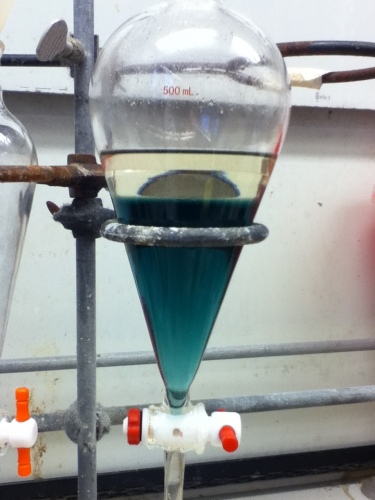

The reaction is complete, so the reaction is cooled and I turn that mini work-up I just did into a maxi work-up in the big separatory funnel. A bit of an emulsion is dealt with by addition of some sodium chloride solution. The solution of my product and assorted impurities is then absorbed on Celite for solid phase loading onto the chromatography apparatus.

Back in the old days, all the purification was done by hand in mind numbing tedium. Nowadays it is all automated with disposable silica cartridges and pumping automatically altering the solvent mixtures for optimal separation. Well, that is the theory anyway. It is considerably less mind-numbing but not always smooth sailing.

Today my column set up well, but when you need it to behave it always wants to be a little mischievous. I set it going and from having done it before I knew when to expect the compound to elute (and you see a nice UV trace on the screen to reassure you of that fact). Well a little peak comes out and it is not at all what I am expecting, for I put a good amount of there and I want a BIG peak. I frown at the screen, concerned. Another peak comes out – perhaps this is the one? But no, again it is but a tiny hillock when I am looking for a mighty mountain.

Then I notice that the test tube fractions collected are coming out half filled. The pump for the polar solvent is misbehaving.

I comfort myself with the fact that the more polar solvent is already at 100%, so the misbehaving pump shouldn’t affect the column from here on out, though it probably made the gradient less steep than was planned, delaying elution. But then a big peak starts coming out and all is right with the world again. Peak shape is a little ugly. But I can live with that. Then as the peak is coming off, another big peak starts to elute.

This was not according to the scheduled program. The TLC had shown no starting material and only faint spots of any other type. What was this monstrosity?

Well, TLC soon told me that the peak shape was so ugly that it had split into a double headed peak. It was all my compound. So just need to strip it down to dryness for a quick NMR analysis before setting up the next step.

There are two possible states for the NMR machine on a Saturday afternoon. The first is that it sits idle and no one has touched it for hours. But because no one much uses it over the weekend, it is a good time for setting up long carbon-13 experiments and once in a while a couple of those will get queued up and black out any possible NMR time until Sunday night. So it is with some trepidation that I take my NMR tube of compound and deuterated chloroform to the room. And a sigh of relief as I find it all sitting idle.

The analysis confirms what I really knew already, as the white solid on the inside of the flask was clearly (by retinal analysis) the purest and best. So into the next step we go.

I keep some back, as this next reaction can be capricious. It is a cyclization reaction and depending on substituents on the parent molecule, gives different yields, but also is variable in the recovery from batch to batch. I’m putting nice material in, so I am giving it the best chance, though one of the substituents is slightly unfavorable.

In true #realtimechem fashion, I was running the TLC as I typed that. And now I have checked it and the reaction is complete.

My Saturday is about done.